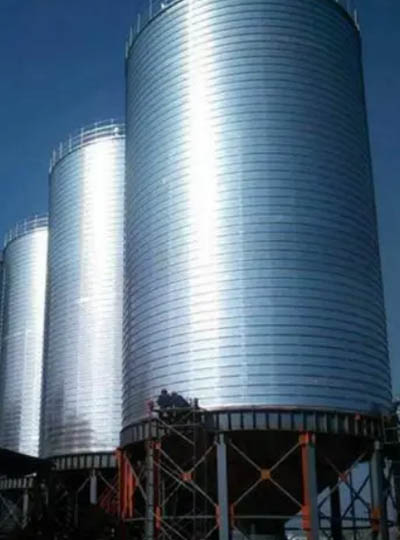

Warehousing facilities play a crucial role in various industries, agriculture, and logistics, and the choice of construction materials significantly impacts the functionality and longevity of these structures. This article aims to provide readers with a comparative analysis of steel silos and concrete silos, highlighting their respective advantages and disadvantages.

1, Strength and Durability:

Steel Silos:

Steel silos exhibit high strength and durability due to the inherent properties of steel plates. Steel surpasses concrete in strength and stability when subjected to forces. The ability to design steel plates with curved surfaces enhances their resistance to wind and earthquakes. Moreover, steel is resistant to corrosion, moisture, oxidation, and mold, ensuring an extended service life.

Concrete Silos:

Concrete silos, while durable, often require increased thickness or reinforcing materials to achieve comparable strength. They are susceptible to environmental factors that can affect their longevity. The maintenance of concrete structures might be more demanding, and their durability is influenced by factors like weathering and exposure.

2, Cost and Construction Difficulty:

Steel Silos:

Steel warehouses are relatively cost-effective, primarily due to the lower cost of steel and the quick construction and installation processes. Steel structures offer flexibility, allowing for partial dismantling or modification when needed. This adaptability reduces costs associated with changes or alterations over time.

Concrete Silos:

Concrete warehouses tend to be more expensive to construct and install. The process involves significant manpower and machinery, and the construction itself is complex. Once a concrete warehouse is built, making changes becomes challenging, contributing to higher overall costs.

3, Applicable Environment and Usage Scenarios:

Steel Silos:

Steel warehouses are well-suited for scenarios that demand quick construction, easy resizing, and flexible movement. The modular design of steel silos allows for rapid responses to market demands, making them suitable for temporary warehouses or facilities like temporary toilets.

Concrete Silos:

Concrete silos are ideal for situations requiring long-term use and high-strength support. They find application in storing important assets, factory production workshops, and other areas where stability and permanence are paramount.

In summary, both steel silos and concrete silos have obvious advantages and disadvantages. The choice between them depends on specific requirements and priorities. If you need a silo that can be quickly built, resized or moved, a steel silo is recommended. On the other hand, for storage needs that require long-term use and sturdy support, opting for concrete silos is more appropriate. Ultimately, decisions should be aligned with the specific needs and goals of the relevant warehousing scenario.

Leave a Reply